Carbon Gravel Frameset with Integrated Stem Handlebar

Carbon Gravel Frameset with Integrated Handlebar or Stem

| Model No. | FM071 |

| Material | High modulus Toray T700 carbon fiber |

| Size | 49, 52, 55, 58(cm) |

| Fork | Specify carbon fork, 450+-15g |

| Stem size | 90/100/110/120mm, 140+-5g |

| Headtube | Straight 1 1/2” head tube(upper 52mm lower 52mm) |

| Weight(+-40g) | 990g/49cm |

| 1020g/52cm | |

| 1050g/55cm | |

| 1100g/58cm | |

| Seatpost | 27.2mm*400mm (with 25mm offset), 180+-5g |

| Bottom bracket | Press-Fit BB86 |

| Max tire clearance | 700*53C or 650B*2.1” |

| Max Chainring | If use single chainring, max 42T (corresponding chainline=49.7mm ). |

| If use double chainring, max 54/42T (chainline=43.5mm), min 46-30T (chainline=47mm) | |

| Brake mount type | Shimano flat mount disc brake (disc brake bolts length 38.2mm) |

| Dropout | Front 12*100mm TA Rear 12*142mm TA |

| Groupset | Mechanical and Di2 compatible(Not compatible with old rear derailleur without B-LINK, eg old 105 5800) |

| Test Standard | ISO4210 |

| Warranty | 2 years |

Notice: If the max teeth of your cassette larger than 42T(such as 11-44T, 11-46T, etc), you need to install an extended hanger as below picture:

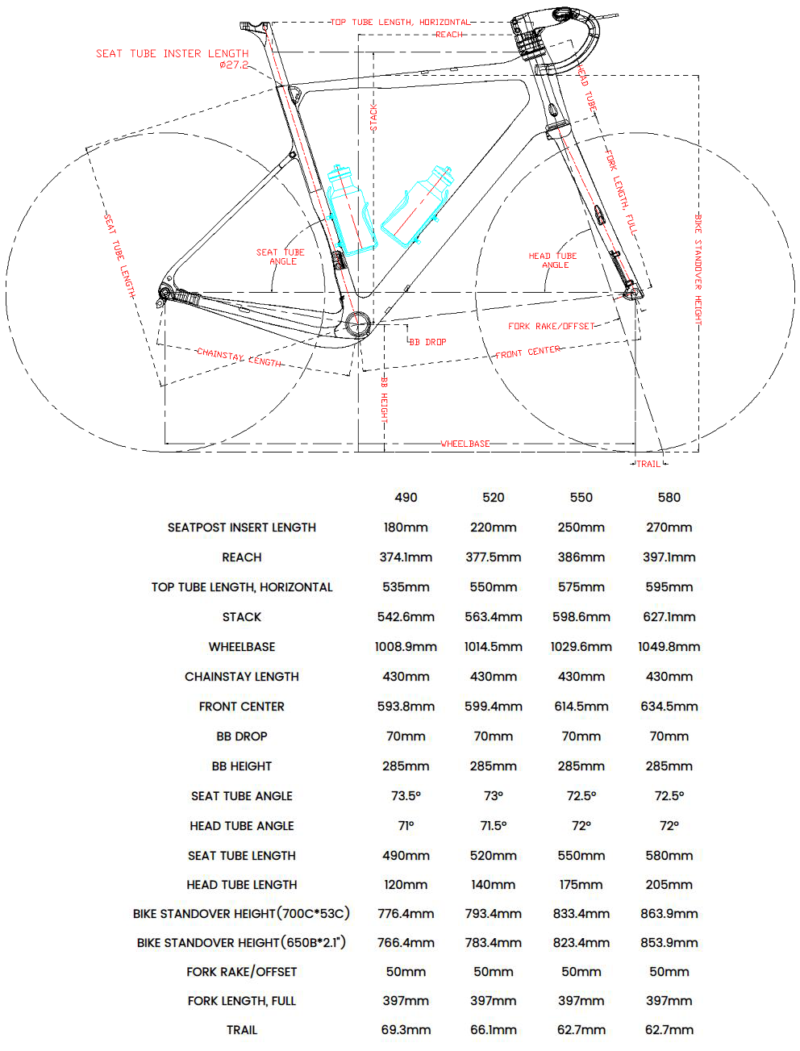

Carbon gravel frameset geometry and size chart

Gravel Frameset internal cable routing

A – Rear derailleur cable routing

B – Rear disc brake cable routing

C – Front Derailleur cable routing

D – Front disc brake cable routing

All cables were integrated though handlebar stem through head-tube, integrated design to make complete bike clean and aerodynamic.

25mm Offset Special Design Top Tube

25mm offset seat post, providing better comfort ability for long distance cycling. Top tube shaved off at the position near seat tube, which helps to reduce vibration and result in better comfort ability.

3D latex mandrel Technology on gravel frame production

Use the newest one-piece latex 3D mandrel and molding technology.

Even using the same material, the strength is improved 30%.

Tradition method and 3D latex mandrel produce Products Compare

One-piece 3D latex mandrel helps to make smooth inner side of frame.

To achieve same strength, tradition method requires thickness 1mm-1.2mm, while such new technology only requires 0.5mm-0.8mm thickness. Thus, we are able to make the frame about 15% lighter, given strength unchanged

The above picture shows frame made with tradition technology and new 3D latex technology, for tradition method which is with many wrinkle and bubble inside. For 3D latex mandrel which is smooth inside, no wrinkle or bubble.

3D latex mandrel produced Gravel Frame cross-section view:

SEND INQUIRY